Impacto das Vibrações na Fadiga de Condutores de Alumínio: Uma Nova Abordagem de Teste

DOI:

https://doi.org/10.14295/vetor.v34i2.18318Palavras-chave:

Condutor Alumínio Liga, Linha de Transmissão, Autoamortecimento, Vibração Eólica, FadigaResumo

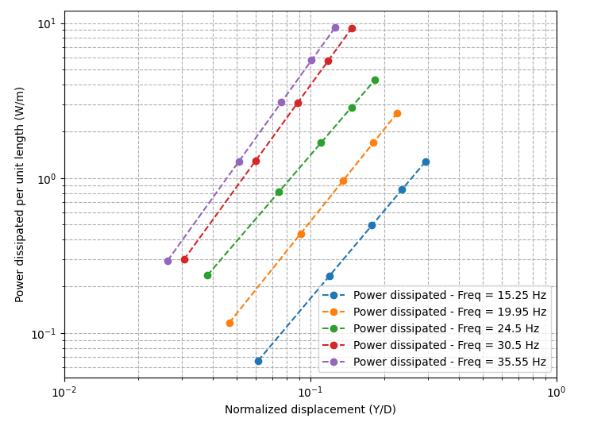

Nas linhas de transmissão, as vibrações induzidas pelo vento, como vibrações eólicas de alta frequência e o fenômeno de galope de baixa frequência, podem causar danos por fadiga e falhas, particularmente em condutores de alumínio, que têm maior flexibilidade. As cargas de vento são forças variáveis aplicadas pelo vento às estruturas, incluindo os condutores. Essas cargas dinâmicas variam de acordo com o clima e a altitude onde os condutores estão localizados, causando dissipação de energia mecânica devido ao atrito dos fios, especialmente nas zonas de contato. Para garantir estabilidade e segurança, essas cargas e o efeito de amortecimento devem ser considerados no planejamento dos sistemas de transmissão elétrica. O objetivo deste estudo é investigar o impacto das cargas de vento nas características de autoamortecimento do condutor, utilizando uma nova abordagem para testes de autoamortecimento. De fato, um teste de autoamortecimento foi realizado no laboratório de fadiga da Universidade de Brasília, utilizando o condutor 838 MCM, CAL 1120. A bancada experimental foi operada em frequências variando de 15,25 a 35,55 Hz, com o parâmetro de catenária H/w = 2143 m, representando a razão entre a carga horizontal inicial (H) e o peso do condutor (w) por unidade de comprimento. A potência dissipada por unidade de comprimento foi calculada pelo método da potência, Ele utiliza uma metodologia que permite medir com precisão a dissipação de energia mecânica. A análise revelou que as frequências mais altas levam a uma maior dissipação de energia. Amplitudes normalizadas mais elevadas em relação ao diâmetro do condutor (Y/D) resultam em maior dissipação na mesma frequência. Esse aumento segue um comportamento de lei de potência, típico de sistemas vibratórios onde a energia dissipada depende da frequência e da amplitude.

Downloads

Referências

J.-P. Hou, Q. Wang, H.-J. Yang, X.-M. Wu, C.-H. Li, Z.-F. Zhang, and X.-W. Li, “Fatigue and Fracture behavior of a Cold-Drawn Commercially pure aluminum wire,” Materials, vol. 9, no. 9, p. 764, 2016. Available at: https://doi.org/10.3390/ma9090764

J. A. Redford, M. Gueguin, M.C. Nguyen, H.-P. Lieurade, C. Yang, F. Hafid, and J.-M. Ghidaglia, “Calibration of a numerical prediction methodology for fretting-fatigue crack initiation in overhead power lines,” International Journal of Fatigue, vol. 124, pp. 400–410, 2019. Available at: https://doi.org/10.1016/j.ijfatigue.2019.03.009

A. A. Fadel, D. Rosa, L. B. Murça, J. L. A. Fereira, and J. A. Araújo, “Effect of high mean tensile stress on the fretting fatigue life of an Ibis steel reinforced aluminium conductor,” International Journal of Fatigue, vol. 42, pp. 24–34, 2012. Available at: https://doi.org/10.1016/j.ijfatigue.2011.03.007

C. Poon, S. U. Mhurchadha, R. A. Barrett, and S. B. Leen, “Three-dimensional representative modelling for fretting wear and fatigue of submarine power cable conductors,” International Journal of Fatigue, vol. 184, 2024. Available at: https://doi.org/10.1016/j.ijfatigue.2024.108302

P. H. C. Rocha, S. Langlois, S. Lalonde, J. A. Araújo, and F. C. Castro, “Influence of 1350 and 6201 aluminum alloys on the fatigue life of overhead conductors – A finite element analysis,” Tribology International, vol. 186, 2023. Available at: https://doi.org/10.1016/j.triboint.2023.108661

R. B. Kalombo, J. M. G. Martínez, J. L. A. Ferreira, C. R. M. Da Silva, and J. A. Araújo, “Comparative Fatigue Resistance of Overhead Conductors Made of Aluminium and Aluminium Alloy: Tests and Analysis,” in Procedia Engineering, vol. 133, 2015, pp. 223–232. Available at: https://doi.org/10.1016/j.proeng.2015.12.662

M. A. Garcia, R. K. Badibanga, J. A. Araújo, J. L. A. Ferreira, and C. R. Moreira da Silva, “Fretting fatigue tests on 6201-T81 aluminum alloy conductor wires at room temperature and 75 °C,” Wear, vol. 548–549, p. 205321, 2024. Available at: https://doi.org/10.1016/j.wear.2024.205321

A. V. Silva, M. A. Costa, H. Ahn, and A. L. M. Lopes, “Performance benchmarking models for electricity transmission regulation: Caveats concerning the Brazilian case,” Utilities Policy, vol. 60, p. 100960, 2019. Available at: https://doi.org/10.1016/j.jup.2019.100960

M. Shahbaz, G. Gozgor, and S. Hammoudeh, “Human capital and export diversification as new determinants of energy demand in the United States,” Energy Economics, vol. 78, pp. 335-349, 2019. Available at: https://doi.org/10.1016/j.eneco.2018.11.016

S. K. Teegala and S. K. Singal, “Optimal costing of overhead power transmission lines using genetic algorithms”, International Journal of Electrical Power and Energy Systems, vol. 83, pp. 298-308, 2016. Available at: https://doi.org/10.1016/j.ijepes.2016.04.031

N. Kannan and D. Vakeesan, “Solar energy for future world: - A review,” Renewable and Sustainable Energy Reviews, vol. 62, pp. 1092-1105, 2016. Available at: https://doi.org/10.1016/j.rser.2016.05.022

C. A. Cimini and B. Q. A. Fonseca, “Temperature profile of progressive damaged overhead electrical conductors,” International Journal of Electrical Power and Energy Systems, vol. 49, no. 1, pp. 280-286, 2013. Available at: https://doi.org/10.1016/j.ijepes.2012.12.015

T. Ishihara and T. Li, “Numerical study on suppression of vortex-induced vibration of circular cylinder by helical wires,” Journal of Wind Engineering and Industrial Aerodynamics, vol. 197, p. 104081, 2020. Available at: https://doi.org/10.1016/j.jweia.2019.104081

F. Luo, C. Gao, and W. Zhang, “The key to suppress vortex-induced vibration: Stability of the structural mode,” Journal of Fluids and Structures, vol. 113, p. 103692, 2022. Available at: https://doi.org/10.1016/j.jfluidstructs.2022.103692

W. L. Chen, Q. Q. Zhang, H. Li, and H. Hu, “An experimental investigation on vortex induced vibration of a flexible inclined cable under a shear flow,” Journal of Fluids and Structures, vol. 54, pp. 297–311, 2015. Available at: https://doi.org/10.1016/j.jfluidstructs.2014.11.007

H. Y. Guo and M. Lou, “Effect of internal flow on vortex-induced vibration of risers,” Journal of Fluids and Structures, vol. 24, no. 4, pp. 496–504, 2008. Available at: https://doi.org/10.1016/j.jfluidstructs.2007.10.002

P. W. Bearman, “Vortex shedding from oscillating bluff bodies,” Annual review of fluid mechanics, vol. 16, pp. 195-222, 1984. Available at: https://doi.org/10.1146/annurev.fl.16.010184.001211

T. Sarpkaya, “Vortex-Induced Oscillations a Selective Review,” Journal of Applied Mechanics, Transactions ASME, vol. 46, no. 2, pp. 241-258, 1979. Available at: https://doi.org/10.1115/1.3424537

G. Diana, M. Falco, A. Cigada, and A. Manenti, “On the measurement of overhead transmission lines conductor self-damping,” IEEE Transactions on Power Delivery, vol. 15, no. 1, pp. 285-292, 2000. Available at: https://doi.org/10.1109/61.847264

F. Foti and L. Martinelli, “An enhanced unified model for the self-damping of stranded cables under aeolian vibrations,” Journal of Wind Engineering and Industrial Aerodynamics, vol. 182, pp. 72-86, 2018. Available at: https://doi.org/10.1016/j.jweia.2018.09.005

T. Barbosa de Miranda, R. K. Badibanga, J. A. Araujo, and J. Ferreira, “Self-damping of conductors AAC, AAAC and ACSR with respect of H/W parameter”, in 25th ABCM International Congress of Mechanical Engineering, Uberlândia, Brazil: ABCM, 2019. Available at: https://doi.org/10.26678/abcm.cobem2019.cob2019-1666

IEC 62567, Overhead lines: methods for testing self-damping characteristics of conductors, 1st Edition, International Electrotechnical Commission and Technical Committee 7: Overhead electrical conductors. 2013.

IEE Std 664TM-1993 (R2007), “IEEE guide for laboratory measurement of the power dissipation characteristics of aeolian vibration dampers for single conductors,” in IEEE Std 664-1993. pp. 1-24, 1993. Available at: https://doi.org/10.1109/IEEESTD.1993.119669

K. W. Barber and K. J. Callaghan, “Improved overhead line conductors using Aluminium Alloy 1120,” in Proceedings of the IEEE Power Engineering Society Transmission and Distribution Conference, Chicago, IL, USA: IEEE, 1994, pp. 528-534. Available at: https://doi.org/10.1109/TDC.1994.328420