Structural Dimensioning of an Equipment to Sinter Refuse of Recycled PET

DOI:

https://doi.org/10.14295/vetor.v31i2.13751Keywords:

Polyethylene terephthalate (PET), Sintering, Structural dimensioning, Finite element analysis, Hydraulic systemAbstract

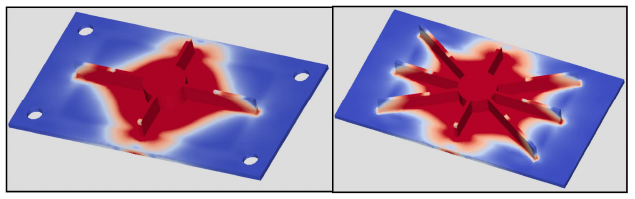

The consumption of polyethylene terephthalate (PET) has been increasing every year, as well as its recycling process as the applications of recycled PET are diversified. However, the recycling companies are not able to recycle 100% of PET because the particles with low granulometry (refuse) are not utilized because they stick to the extruder screw and are discarded. This study presents the structural dimensioning of a proposal of an equipment to sinter this refuse in some predetermined geometries, in order to achieve possible commercial applications. This structural dimensioning was done with finite element analysis open-source software Salome Meca. Some structural modifications required to achieve the design requirements are presented. Yet, the hydraulic system to operate the compression was also dimensioned.

Downloads

References

ABIPET. Brazilian PET Industry. Available at:

http://www.abipet.org.br/uploads/File/Market%20Overview%202013.pdf.

W. F. Costa, Avaliação da Viabilidade de Obtenção de Peças Densas a Partir do Processo de Prensagem a Quente de Pó de Polietileno Tereftalato (PET) Reciclado. Bachelor thesis, Mechanical Engineering, Federal University of Juiz de Fora - UFJF, Brazil, (in Portuguese), 2016.

A. F. Ávila and M. V. Duarte, “A mechanical analysis on recycled PET/HDPE composites,” Polymer Degradation and Stability, vol. 80, no. 2, pp. 373–382, 2003. Available at: https://doi.org/10.1016/S0141-3910(03)00025-9

A. L. F. M. Giraldi, J. R. Bartoli, J. I. Velasco, and L. H. I. Mei, “Glass fibre recycled poly(ethyleneterephthalate) composites: mechanical and thermal properties,” Polymer Testing, vol. 24, no. 4, pp. 507-512, 2005. Available at: https://doi.org/10.1016/j.polymertesting.2004.11.011

A. L. F. M. Giraldi, R. C. Jesus, and L. H. I. Mei, “The influence of extrusion variables on the interfacial adhesion and mechanical properties of recycled PET composites,” Journal of Materials Processing Technology, vol. 162-163, pp. 90-95, 2005. Available at: https://doi.org/10.1016/j.jmatprotec.2005.02.046

R. M. Meri, J. Zicans, R. Maksimovs, T. Ivanova, M. Kalnins, R. Berzina, and G. Japins, “Elasticity and long-term behavior of recycled polyethylene terephthalate (rPET)/montmorillonite (MMT) composites,” Composite Structures, vol. 111, pp. 453-458, 2014. Available at: https://doi.org/10.1016/j.compstruct.2014.01.017

N. E. Zander, M. Gillan, Z. Burckhard, and F. Gardea, “Recycled polypropylene blends as novel 3D printing materials,” Additive Manufacturing, vol. 25, pp. 122-130, 2019. Available at: https://doi.org/10.1016/j.addma.2018.11.009

D. V. Shatokha, Sintering - Methods and Products. Rijeka: InTech, 2012.

Ferreira G.A. (2017), Avaliação das propriedades mecânicas de peças densas a partir do processo de prensagem a quente de pó de polietileno tereftalato (PET) reciclado. Bachelor’s thesis, Mechanical Engineering, Federal University of Juiz de Fora - UFJF, Brazil, (in Portuguese), 2017.

G. Cipriano Jr., A Influência dos Parâmetros de Sinterização nas Propriedades Mecânicas do Refugo de PET. Bachelor’s thesis, Mechanical Engineering, Federal University of Juiz de Fora - UFJF, Brazil, (in Portuguese), 2019.

ABNT, Associação Brasileira de Normas Técnicas, NBR 8800:2008, Projeto de estruturas de aço e de estruturas mistas de aço e concreto de edifícios, Rio de Janeiro, (in Portuguese), 2008.

A. B. Fialho, Automação Hidráulica: projetos, dimensionamento e análise de circuitos, 4th ed., São Paulo, Brazil: Érica, (in Portuguese), 2006.

Downloads

Published

Versions

- 2021-12-19 (2)

- 2021-12-17 (1)